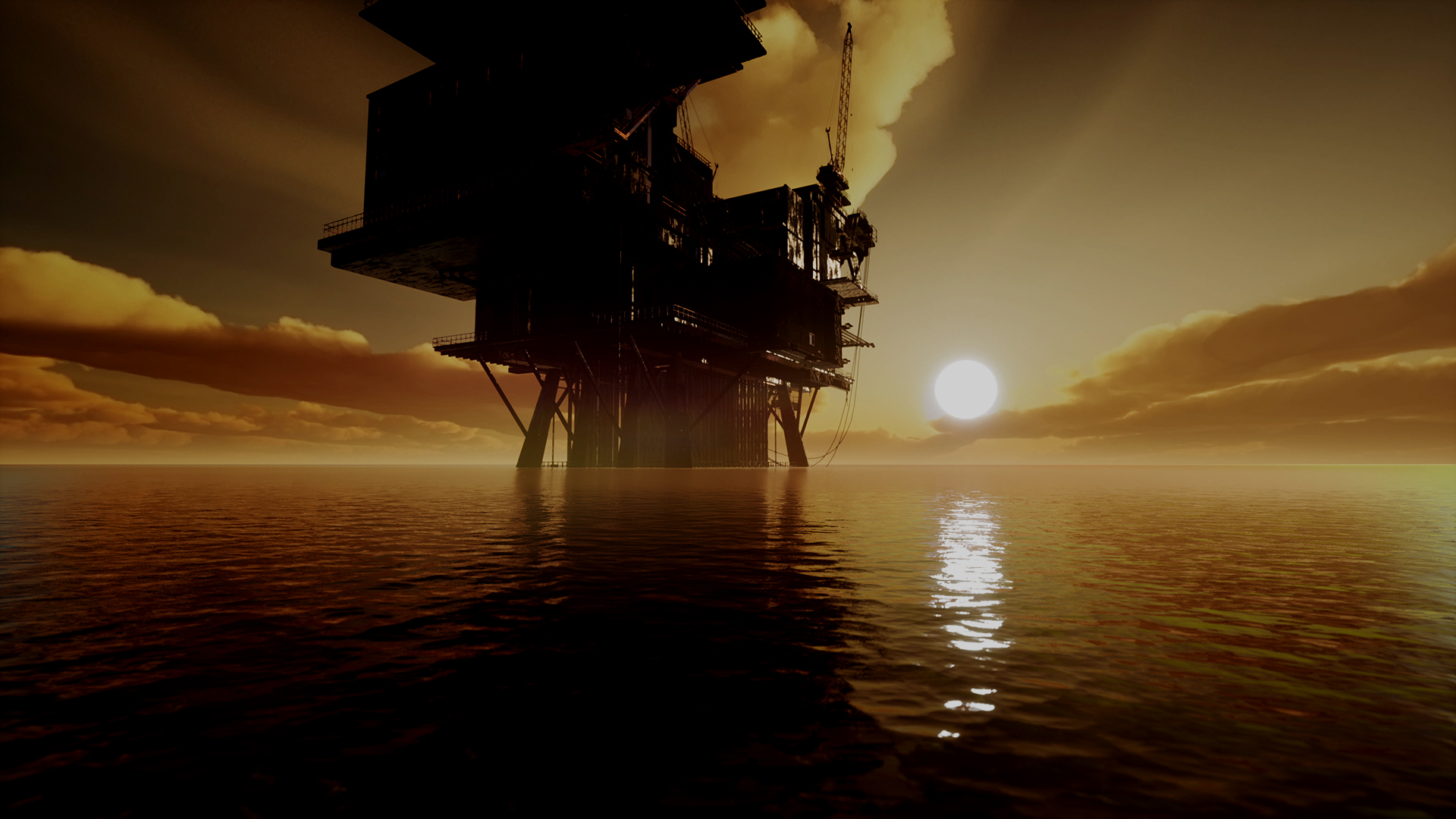

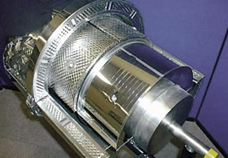

끊임없는 혁신으로

엔지니어링 제품의 설계 및 제조분야의 리더를 꿈꿉니다.

㈜다마텍엔지니어링 기업 정보Learn more

영국 다켐엔지니어링

-

70Year

Established in 1953

-

10,000People

About 10,000 business members

-

6,971Expert Experience

Years of

Combined Expert Experience 6,971